English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик

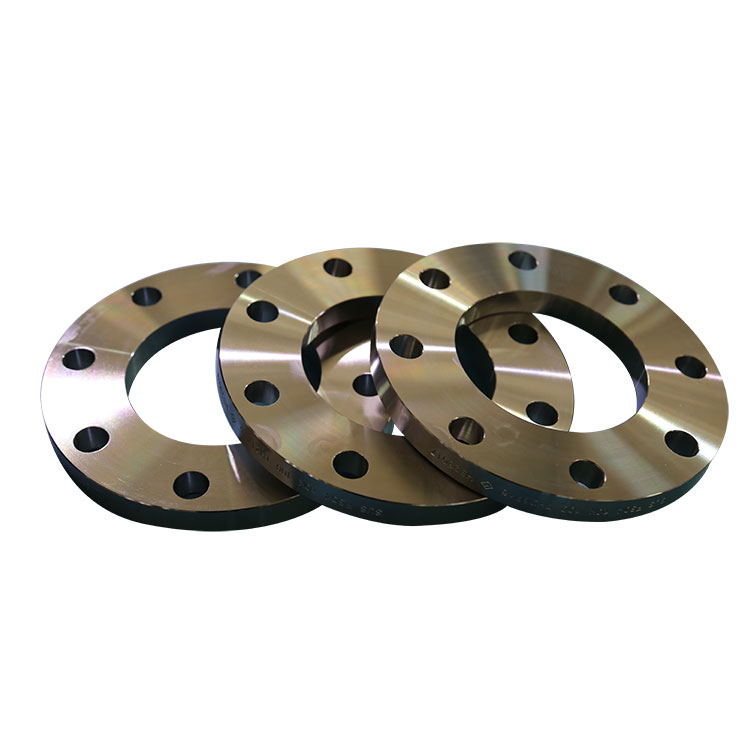

Sliding Flange

As one of the professional China Sliding Flange manufacturers and China Sliding Flange suppliers, we are strong strength and complete management. Also, we have own exporting license. We mainly deal in making a series of Cap mould and so on.

Send Inquiry

Sliding Flange

Innovative products and predominant quality enable Huaxi to be bigger, stronger and better on the way to be leadership. Currently, circular foundry parts, flanges and pipe fittings which are produced by Huaxi have been widely applied to wind power generation, nuclear power generation, ship, pressure vessels, petrochemical, machinery manufacturing, aviation and aerospace and military.

Jiangyin Huaxi Flange Co., Ltd., a subordinate enterprise of Jiangsu Huaxi Group Co., Ltd., is the enterprise of flanges and pipe fittings in China.Founded in 1984, the factory specializes in the production of outlet flanges.In 1990, the factory established Jiangyin Huaxi Flange Co., Ltd., with Singapore Towa Hardware Private Co., Ltd. In 2005, the company implemented the technology reform extension project, purchased 3z600t oil hydraulic presses, 5m ring mills, 8t and 5t electro-hydraulic hammers,2-5m vertical lathes, 5m NC drilling machines, heat treatment furnaces and other ring-type forgings production equipment, and realized strategic adjustment to the core products of the enterprise. At present, the company has a floor area of 150,000 square meters, a plant area of 80,000 square meters, and more than 1,000 people including 115 high/middle-level technical personnel. The company annually produces 35,000 tons of ring-type forgings and 25,000 tons of finished flanges and pipe fittings made from stainless steel carbon steel alloy steel, dual-phase steel and many other materials, with over 10,000 specifications and varieties. The products have been exported to 28 countries and areas, such as Japan, America, France, Germany, Italy, etc. With self-run import & export right, the company is capable of directly taking foreign customers' orders, producing standard flanges and pipe fittings in accordance with JIS, ANSI, EN, DIN, BS and GB domestic and international standards, and producing ring-type forgings, non-standard flanges and pipe fittings according to customers* drawings or samples.

The company boasts its perfect quality guarantee system and a whole set of modern physicochemical inspection equipment. In recent years, the company successively passed the certifications of ISO9001 and German TUV Rhine IS09001&PED, and got the authorization certificate of China Classification Society, the manufacture license of special equipment (pressure pipeline), the Class-A export enterprise assessment

certificate of AQSIQ, the BV factory approval certificate, the member certificate of China Forging Association, the safety registration certificate of steel forging products for pressure vessels and the member certificate of Wind Power Machinery Branch Association.

Product Parameter

|

Size range: |

seamless 1/2" to 24" seam weldding 4" to 48" |

|

Material: |

carbon steel ASTM A234 wpb, wpc; A106; st37.0; S235JR; SS400; CT20, 20#; Q235A; Q235B |

|

Standard:

|

ANSI B16.5, ASME B16.47, ANSI B16.9, ASME B16.28 DIN2573, DIN2576, DIN2502, DIN2503, DIN2642, DIN2643,DIN2565, DIN2566,DIN2527,DIN2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2655, DIN2656 DIN 2605, DIN 2615, DIN2616,DIN2617; GOST 12820-80, GOST 12821-80, GOST 17375, GOST17376 GOST 17378; JIS B2220, JIS B2311, JIS B2312, JIS B2313 EN1092-1, BS4504, SABS1123, |

|

Wall thickness: |

2MM----25MM SCH5,SCH10S, SCH10, SCH20, SCH30, STD, SCH40, XS, SCH60, SCH80, SCH100, SCH120, SCH140, SCH160, XXS, SGP, LG, |

|

Products: |

welding neck, slip on, blind, plate, loose, threaded, lap joint |

|

Flange: |

45 deg, 90 deg, 180 deg, long redius, short redius |

|

Elbow: |

equal, reducing |

|

Tee: |

concentric, eccentric, |

|

Reducer: |

|

|

Cap |

|

|

Cross |

|

|

Coating:b |

lack paint, rust-proof oil, transparent paint, hot galvanized, cold galvanized |

|

Packing: |

seaworthy plywood crate,fumigation free woodedn pallet |

The Process Flow

Production Equipment

Qualification Certificate